An article in a recent edition of DAN’s Alert Diver magazine warns of the perils of diving with an isolator valve you only think is open (link below). While your SPG may be telling you that you have phenomenal gas consumption, the reality is that you are sucking the right side of your doubles dry and may soon run out of air without warning. This story hit close to home for me, as I’ve witnessed this same situation twice…and experienced it once.

An article in a recent edition of DAN’s Alert Diver magazine warns of the perils of diving with an isolator valve you only think is open (link below). While your SPG may be telling you that you have phenomenal gas consumption, the reality is that you are sucking the right side of your doubles dry and may soon run out of air without warning. This story hit close to home for me, as I’ve witnessed this same situation twice…and experienced it once.

Each of these three situations had different root causes, and each teaches one or more lessons in its own right. Let’s take a look at each situation and what you can learn from it.

Open a partial turn?

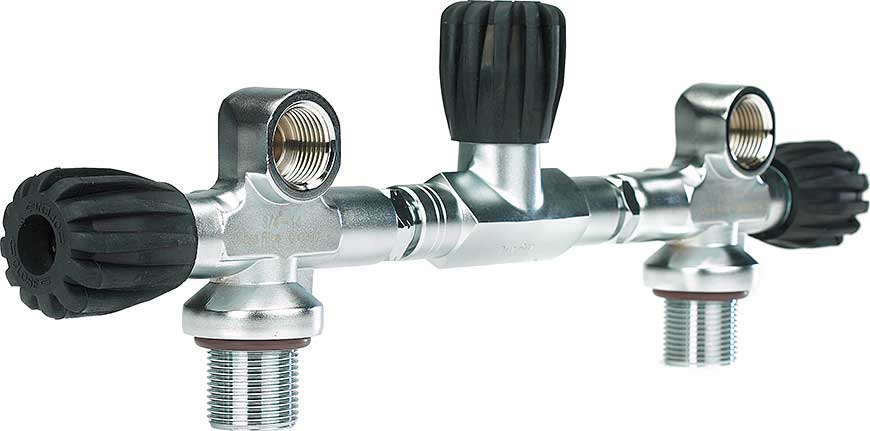

This story goes back nearly 20 years, to what my friends call Harry’s Hogarthian Phase (i.e., the days before sidemount). Some of my fellow cave instructors were espousing an approach to diving manifolded doubles in which you opened your isolation valve just a partial turn. The idea was that, should something start to leak badly, you could isolate almost instantly and, thus, safe half your remaining air. This seemed logical to me, so I started doing it.

Everything worked fine until the Dive Rite gang and I made our first trip aboard Rick Pitts’ Ultimate Getaway. We were diving a wreck at 130 feet. I was using a set of manifolded steel 72s I’d put together just for this trip (a sweet setup if you do not need a lot of gas).

When diving manifolded doubles in caves, I’ve always made a practice of starting each dive by reaching back and confirming the position of all three valves while standing in chest-deep water. At sea, this wasn’t an option, so I did it while standing on a rocking boat deck.

Five minutes into the dive, I was marveling at my exceptional gas consumption. My SPG showed that I’d only used a couple of hundred pounds (actually a result of the tanks cooling).

Ten minutes into the dive, with my SPG not having moved past this, I decided Something Was Wrong and called the dive. In retrospect, what I was seeing should have been a clear warning of a closed isolator, and my response should have been to double check the position of all three valve turnwheels. However, being as I was a conscientious diver and had checked this prior to the dive, I assumed it had to be something else, like a faulty SPG.

Upon surfacing, I noticed that the first stage on my right post was moving rather freely. Out of curiosity, I tried detaching it from the tanks without first shutting down the valve. It came right off in my hand. This meant that, while I was fighting rough seas trying to get back on the boat, I was mere seconds from running out of gas (whoops!).

So what had happened? Apparently, prior to the dive, the boat lurched while I was checking the position of the isolator valve. As a result, I inadvertently closed the valve while thinking it was still open a partial turn.

Lessons learned: There are actually three:

- To start, your isolator is like your other two valve turnwheels; it should be all the way open or all the way closed. In fact, except in an emergency, it should never be anything but all the way open. Yes, if need be, it will take a little longer to isolate — but it won’t put you at risk of being suddenly without air. A partially open isolator is too easily closed by accident.

- Second, beware suspiciously good gas consumption. No, your breathing rate didn’t improve miraculously. Gas consumption that’s too good to be true actually means something isn’t right.

- Finally, check your turnwheels. It should be the first thing you do if you don’t appear to be using any gas. Yes, we know you checked them at the surface; check them again. You may be surprised at what you find. And you may be able to save your life, if not the dive.

Make sure you fully understand your manifold before using it

These days, most cave instructors want students to have prior experience in backmounted doubles before using them in a course. This wasn’t always the case. Before tech diver training became widely available, a Cave Diver course often provided a student’s first introduction to doubles.

This was the case some years ago when I had a student in his second day of training on doubles. Prior to the first dive of the day, I had the student reach back and check all three valves, to confirm they were all the way on. He did — although his head blocked my view of exactly what he was doing when checking his isolator valve.

While exiting, the student suddenly flashed his light and gave me the out of air signal. I responded by immediately passing a second stage and switching to the other. I then reached back and checked his manifold, starting with the isolator.

You guessed it. It was fully shut, and he’d sucked one half of his doubles dry. Have you ever heard the noise a set of doubles makes when you open the isolator and equalize the pressure between tanks? It’s one you won’t forget.

So what happened? Two things:

- Despite my having spent considerable time on manifold function and operation, the student failed to grasp the part about never shutting your isolator, except in an emergency. So, as the end of the previous day, the student dutifully shut down his outboard valve turnwheels…then did the same with the isolator. He then proceeded to attach the fill whip to the left post, leaving the entire right side of the doubles close ro empty.

- When checking his valve turnwheels prior to the next dive, the student only check to see that the isolator turnwheel was fully turned in a direction…just not the right direction. Had he turned the valve in the opposite direction before checking to make sure it was turned all the way in one direction or the other, he would have heard the sound of gas moving rapidly through the manifold. I would have seen this, except for the fact his head was in the way.

Not only had this never happened to one of my students before, I’d never heard of it happening to anyone else’s. I’d tell you that I always made a point of checking this with students from this point one, but the fact is, after this student, I never had another student who wanted to learn in anything but sidemount.

Lessons learned: Four things here:

- Leave the isolator valve all the way open, all the time (except, of course, in an emergency).

- When filling doubles, check to make sure that both sides are being filled.

- When checking turnwheel position prior to a dive, back off slightly on each valve before turning it all the way in the right direction.

- And, finally, practice manipulating your manifold turnwheels until you are totally clear on which direction is clockwise (off) and counter- or anti-clockwise (on).

Complacency kills

It’s not easy admitting that you’ve screwed up or, worse, allowed a student to screw up. I can, however, take solace in the fact I’m not alone.

This story took place in 2000. It involves a regular dive buddy, Gareth, and another friend whom I’ll save embarrassment and simply refer to as “Herschel.” Herschel is a vastly more knowledgable and experienced cave diving educator than I am — and there are not a lot of people who can say that. Nevertheless, even the best among us can have a bad day.

On this particular day, Herschel had invited Gareth and me to accompany him on a dive in a system that, even now, not many people have seen. We were nearly 2,000 feet back, enjoying what, for us, was an entirely new cave, when we hear a voice behind us go, “Thit! Thummavabith!” We then heard the distinctive sound of gas rapidly rushing from one side of a set of doubles to the other, followed by a flashing of light and a thumbs-up signal, calling the dive early.

So what happened? It seems Herschel had made the same mistake my student had just a few years earlier; he’d filled his doubles with the isolator closed. And, in this case, he couldn’t claim that I hadn’t taught him about that.

Lessons learned: No one is bulletproof. Everyone makes mistakes. They say that, for the first 50 dives, most new cave divers are filled with trepidation, given the graphic images of death and destruction with which their instructors have filled their imaginations. Then, having survived their first 50 or more dives, they start to get complacent. They cut corners. They stop believing it can happen to them. This is when the most fatalities occur.

A friend once said that, if you are very lucky, you will get to make one big mistake…and survive. Whether or not you continue to survive depends on whether you learn from the experience or blow it off. Who knows? You might get lucky. But you probably won’t.

So what have we learned?

Perhaps we can best sum it up this way:

- Isolators are like any other valve. Other than in an emergency, they need to be turned all the way on.

- Don’t fill your doubles until you first check to make sure the isolator is turned all the way on.

- Check to make sure all three turnwheels are all the way on at the start of the dive — but don’t assume that guarantees anything.

- No, your gas consumption will not improve dramatically over the course of just one dive. If your SPG fails to drop more than just a couple hundred pounds within the first ten minutes, stop and check valve position. Fix any problems you find and call the dive if necessary.

- You are not bulletproof — no matter how much experience you have. Never forget the cave is trying its damnest to kill you dead. Don’t let complacency help it along.

Here is a link to the Divers Alert Network article we mentioned earlier. It’s worth a read.